When the Covid-19 pandemic subsides, supply chains across the world are going to look markedly different. The supply shock that started in China in February and the demand shock that followed as the global economy rippled through the economy, exposing vulnerabilities in the company’s production strategies and supply chains. Many manufacturers are restructuring to increase their domestic production, grow employment in their home countries, reduce or even eliminate their dependence on sources that are perceived as risky, and rethink their use of lean manufacturing strategies. The challenge for companies will be to make their supply chains more resilient without weakening their competitiveness.

First, a look at some of the key areas of concern with regard to freight operations will help to understand why so many supply chains have suffered a significant slowdown in recent months.

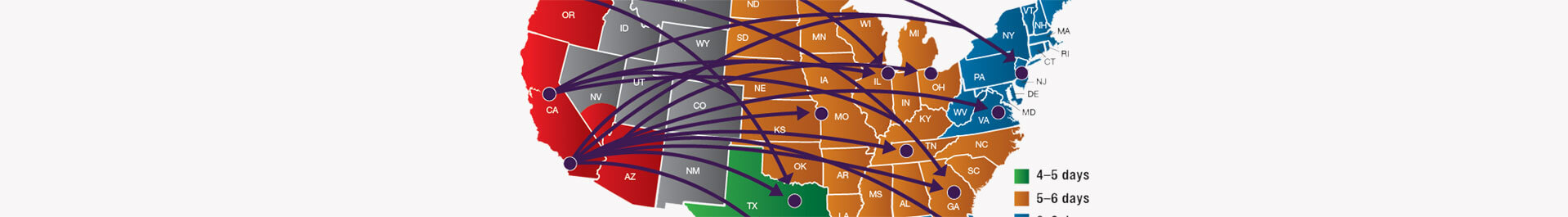

In a June survey of US executives, 44 percent said that a “muted world recovery” scenario seemed most likely: the coronavirus recurs, growth is slow, and GDP does not fully recover until Q1 2023. The recovery for a mode of transport as well as for individual carriers will depend on its commodity exposure; in most scenarios, less-than-truckload (LTL) shipping is likely to grow faster than other modes due to its commodity-mix profiles. LTL shipping carries a heavy proportion of fast-to-return agriculture, food, and services and benefits from growth in e-commerce. As a trusted, economical long haul LTL service provider, Clear Lane’s business model is simple: utilize technology to build a non-asset based network using the available capacity of regional LTL partners for reliable pickup and delivery service. In addition to greater capacity and price advantage, Clear Lane’s intermodal model provides a safer and more environmentally friendly method of moving freight in long haul lanes.

Understanding where the risks lie so that your company can protect itself. A good first step is to map out your full supply chain, including distribution facilities and transportation hubs. A surprise disruption can bring your business to a halt, which can be very costly. When mapping, categorize suppliers as low-, medium-, or high-risk. This will help you identify how quickly a disruption along the supply chain could take to either recover or be replaced by alternate options. Once you’ve identified the risks in your supply chain, you can use that information to address them by either diversifying your sources or stockpiling key materials or items.

To reduce dependence, when possible, add more sources in locations not vulnerable to the same risks. For many international companies, this has meant reducing dependence on China especially in terms of production. Your company may want to consider a regional strategy of producing a substantial proportion of key goods within the region where they are consumed. When it comes to diversifying to mitigate supply chain risk, Clear Lane Freight is an ideal LTL solution for 3PLs and their customers. By partnering with some of the largest 3PL’s in the industry and their productive sales organizations, Clear Lane is able to reach large numbers of small to medium size shippers.

Companies should use this crisis to take a fresh look at their supply networks, take steps to understand their vulnerabilities, and then take actions to improve robustness. At Clear Lane Freight, we take pride in providing competitive rates and being a one-stop shop for our customers. We have a quotes team to assist with inquires and insurance for those customers that want a little bit more protection. If you are interested in finding more about the services and pricing Clear Lane Freight has to offer, contact our sales team here.

If you are interested in finding more about the services and pricing Clear Lane has to offer, please contact Sales